Product Description

Concrete Patch Repair material for cracks, saw cuts, break joints and

holes in concrete

SealGreen Concrete Patch Repair is a cementitious stainable material design for grouting small hairline cracks, saw cuts or break joints, divots created from the removal of wood carpet strips, and small holes in interior concrete floors.

SealGreen Concrete Patch can be stain, painted or seal. SealGreen Concrete Patch is design for hairline crack repair from 1/32-inches to 1-inch wide cracks or break joints and saw cuts. Do not use this product for resurfacing. Must be installed at temperatures over 50ºF.

Our product quantity recommendation are based on using ASTM regulations for construction. For Break joints or Saw cuts' the standard is 1/3rd inches depth cut of the thickness of the concrete slab by 1/4 inch wide.

Mixing and Application:

Mix small quantities by hand using 3 to 4 parts by volume of powder to 1 part of water. Use a margin trowel and mix vigorously for 2-3 minutes. Mix thoroughly to obtain a lump-free consistency. The pot life of SealGreen Concrete Patch is approximately 20 minutes at 70ºF. If the product begins to set in the bucket, remix before using. Do not add more water. Additional water will weaken the dressing and lower its strength. In warm weather, use cold water to extend the working time.

Recommended Tools

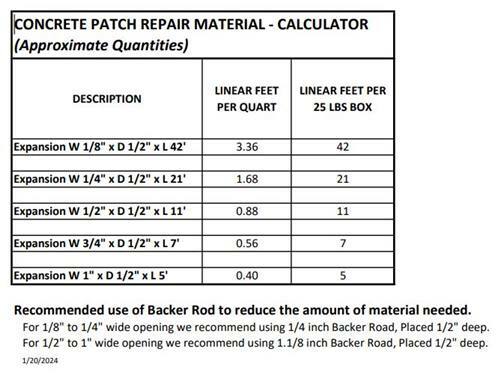

Backer Road information

Mixing buckets, margin trowel, steel trowel, sponges. For small cracks, it is recommended to apply with grout float or sponge using tile grouting practices,

Curing

Requires no special curing procedures, avoid applying this product if rain is expected within 6-8 hours or freezing temperatures could occur within 24 hours of application. As with any cementitious material, the above conditions can alter the appearance and performance of the dressing.

Notes

Mix Ratio: 3 or 4 parts powder to 1 part by volume of water at 70ºF

Walkable: Light Foot traffic in 2 hours. Vehicular traffic in 6-8 hours

Storage: Store in a cool dry area. Do not expose to sun.

Shelf Life: One year

TECHNICAL PRODUCT DESCRIPTION

SealGreen Concrete Patch Repair is a is a cementitious stainable material design for grouting small hairline cracks, divots created from the removal of wood carpet strips, and small holes in interior concrete floors. SealGreen Concrete Patch Repair is ONLY a cementitious filler and it is NOT designed to repair concrete or acquire bonding strength. Concrete Patch Repair is a pre-blended, sanded product. The standard formulation meets ASTM C 270 and C 1714 for Type N mortar.

COLORS: SealGreen Concrete Patch Repair is only available in gray

SIZES: 2 Lbs. Bag, Pack of (3) 2 Lbs. Bags, and 25-Lbs. Box

APPLICABLE STANDARDS

ASTM International

• ASTM C 270 Specification for Mortar for Unit Masonry

• ASTM C 387 Specification for Packaged, Dry, Combined Materials for Mortar and Concrete

• ASTM C 1714 Specification for Preblended Dry Concrete Patch Repair for Unit Masonry

PHYSICAL/CHEMICAL PROPERTIES

SealGreen Concrete Patch Repair meets or exceeds the property requirements of ASTM C 270, ASTM C 387 and ASTM C 1714 for the type selected. Refer to Appendix XI of ASTM C270 for guidance in selecting the proper mortar type. See Table 1.

INSTALLATION

SURFACE PREPARATION: Surfaces to receive Concrete Patch Repair should be clean and free of dirt, loose debris, grease, oil, etc., for the best possible bond.

MIXING

Mix small quantities by hand using 3 parts by volume of powder to 1 part of water. Use a margin trowel and mix vigorously for 2-3 minutes. Mix thoroughly to obtain a lump-free consistency. The pot life of SealGreen Concrete Patch is approximately 20 minutes at 70ºF. If the product begins to set in the bucket, remix before using. Do not add more water. Additional water will weaken the dressing and lower its strength. In warm weather, use cold water to extend the working time.

INSTALLATION

• Apply using a similar method to grouting ceramic tile. Push downward into the concrete crack with a grout float or yellow grouting sponge. Use same process for divots or small hole in concrete. Level the mortar with the concrete surface and let dry.

• Using a sponge sand block, remove all excess material until patch is even with the concrete surface.